● The Basics

● Flat Washers

● Spring Rate and Stacking

● Understanding Load, Stress, and Fatigue Life

● Belleville Spring Specifications

● Presetting

A Belleville washer or disc spring is a conical-shaped spring with an open center. It is shaped much like a washer and is typically smaller than a coiled spring. Because Belleville washers can bear a much larger load relative to its deflection rate than a coiled spring, they are ideal for cushioning heavy loads with short motion.

Like all springs, a Belleville disc spring will deflect in response to a load. Belleville washers and disc springs exhibit low deflections relative to high loads. The relationship between the load and deflection is non-linear, particularly as load increases. This quality makes Belleville washers and disc springs well-suited to areas with constant thrust that must stand up to heavy wear.

Belleville washers and disc springs provide the following advantages:

● Conserve space

● Offer a long service life

● Can be used in conjunction with coiled springs

● Offer great versatility when stacked in series or in parallel

● Increase the reliability of machinery

● Prevent bolt failures

● Maintain the positioning accuracy of ball bearings

● Minimize thermal expansion

● Are self-damping

● Distribute loads evenly

● Absorb shocks

Our engineers can help you determine the washers or springs needed to meet the requirements of your specific application.

In some instances that must bear a heavy load, the addition of a flat washer increases the effectiveness of a Belleville washer or disc spring by helping to spread the load. In other applications, a flat washer can prevent a Belleville washer or disc spring from biting into softer metals. This is particularly important in preserving the integrity of bus bars, which are typically made from aluminum to withstand conditions of high current loading.

Our engineers can help you to determine whether flat washers are needed for your specific application.

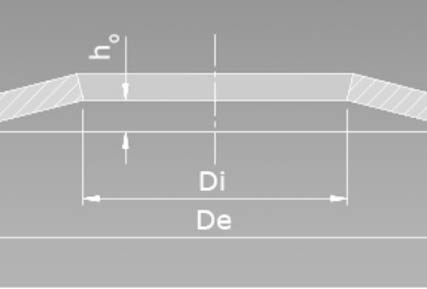

The spring rate of a Belleville washer or disc spring is the amount of force associated with a given deflection measured in lb/in or N/mm. Every spring has its own spring rate, depending on its geometry and material. The formula to determine the load at a specific deflection uses Poisson’s ratio, Young’s modulus, as well as the outside diameter (De), inside diameter (Di), material thickness (t), and deflection-to-flat (ho).

The load/deflection ratio of a specific outer and inner diameter can be changed by using more than one Belleville washer or disc spring, stacked either in series or in parallel. Stacking Belleville washers and disc springs allows for precise customization of the load and/or deflection.

● Stacking in parallel (same direction) will increase load.

● Stacking in series (opposite directions) will increase deflection.

● Belleville disc springs can also be stacked as a combination of the two alignments.

The exact configuration of Belleville washers or disc springs depends on the requirements and limitations of the application. Our engineers can provide assistance in determining the configuration that best meets your needs.

It is also important to know the limits of a given Belleville washer or disc spring before it is put into service in an industrial environment. Calculating load and stress is a way to determine the point of failure for a spring, including Belleville washers and disc springs. Simply put, it’s a way to determine how much force (load) and how much stretch (stress) the spring can bear before it fails.

Fatigue life refers to the number of cycles a spring can withstand before it fails in a particular application. The fatigue life is based on the dimensions of the spring or spring stack, the preload, the final load, the deflection, and the frequency. The goal of determining the fatigue life is to ensure that your Belleville washer or disc spring solution will be able to withstand the stress to which it will be exposed. In situations in which a single Belleville cannot withstand the level of stress, a well-designed stack of Bellevilles can alter the load and stress performance and increase the fatigue life.

Well-designed springs contribute to increased efficiency and prolonged service life for your equipment. Our engineers are always available to provide assistance with all facets of Belleville washer and disc spring design, including load and stress calculations.

The term “tolerance” refers to the amount of deviation from specification that may occur in a disc spring without compromising its performance. For Belleville disc springs, allowable tolerances for diameter, thickness, height, and load are provided in the DIN 2093 specification. Deutsches Institut für Normung (DIN) is an international standards organization, based in Germany that governs specifications of many industrial and technical materials.

Hegong Spring utilizes the following DIN specifications to guide our design and manufacturing process:

● Our engineers employ the calculations of DIN 2092 to create Belleville disc springs with predictable deflection for a given load and a determinable minimum life cycle.

● Hegong Spring adheres to DIN 2093 for the type, dimensions, material, permissible stress, permissible set, guide clearance, and testing of Bellevilles. Although DIN 2093 applies only to specific limited applications and sizes, all disc springs produced by Hegong Spring are manufactured in accordance with the quality and testing requirements contained in this specification.

● Hegong Spring utilizes DIN 6796 in the manufacturing of heavy-duty Belleville washers.

Presetting takes place during the manufacturing process of a Belleville washer or disc spring when it is momentarily flattened. The process reduces the original unloaded height of the spring, as a result of the residual tensile stresses.

Preset Belleville washers and disc springs are typically used to maintain load or tension in bolted assemblies. This process is not always necessary and must be specified at the time the order is placed.