Home > News > Belleville washer review-Your solution to ending problems caused by traditional springs

A coil spring may not work well in confined space that needs high load. What you should be using is a Belleville washer. Go through this Belleville washer review to learn more!

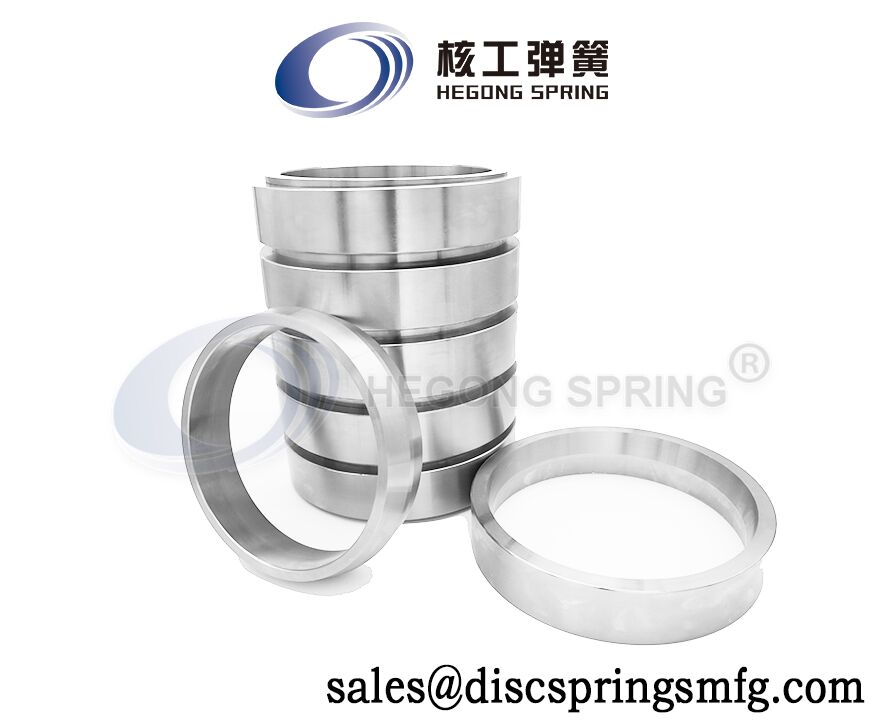

A Belleville washer is a type of compact, washer-shaped spring. Other terms for this item include "conical spring washer," "coned-disc spring," "cupped spring washer" and "Belleville spring." These washers are used for many applications and can be constructed out of various materials, including stainless steel. They are often used to add flexibility to bolted joints. Stacking one Belleville washer atop another in a certain orientation will influence deflection.

Belleville washers are used to solve many problems, such as thermal expansion, bolt creep and vibration-related problems. A Belleville washer is designed to generate a great amount of force in a short, compact spring design. When compressed, a coned-disc spring offers great force with minimal movement. A properly constructed Belleville washer will not relax by a significant amount even when it is under pressure for a period of time. They are designed to withstand years of regular compression without deforming.

Most Belleville washers are constructed out of grades of steel such as carbon steel and stainless steel. A type of steel called 18-8 stainless steel is one of the more popular types of stainless steel that manufacturers use to create Belleville washers. This non-magnetic type of steel contains 18 percent chromium and 8 percent nickel. Chromium and nickel add to the steel’s corrosion resistance.

Carbon steels contain more carbon than other grades of steel. They are easily stamped, forged, machined, cast and wrought into shape. Carbon increases a Bellville washer’s hardness and overall strength.

The average Belleville washer is engineered with an outer coating to increase the desirable properties of the washer’s base metal. Inorganic aluminum and zinc compound coatings contribute to increases in the washer's electrical conductivity and corrosion resistance. Most conical spring washers that are made out of carbon steel feature zinc phosphate coatings to increase corrosion resistance. Nickel plating leaves a Belleville washer with a smooth, even finish. Adding nickel plating to a washer increases the overall corrosion resistance of the spring.

Belleville washers are constructed to fit the sizes of most traditional screws. They have diameters from about 0.2-2.5 inches (4.75-63.5 mm). The diameter of the hole in the middle typically measures about 0.1-1.0 inches (2.54-25.4 mm).

Ever since I bought a race car, I spend most of my weekends on the field trying to win against my friends. I love the thrill of racing, and I don’t view my hobby as a dangerous one. I, however, got into an accident on the field since my brakes failed and my car was not moving at the expected speed. This was a wakeup call for me, and I had to make some major adjustments. A friend recommended installing a Belleville washer which has made a significant difference. It has not only increased the speed of my racecar but also enhanced my brake system.

| Applications | aircraft, fishing reels, target rifles, military landmines, race cars |

| Shape | Frusto-conical |

| Material | Stainless steel |

| Pack | 100 |

| Call to action | Check price here |

In 1876, Julien Belleville came up with a spring design which used the same principle as a disc spring. He named it Belleville washer or a cupped spring washer. Belleville washer is a conical shell that is used as a spring. It is a form of spring washer that is categorized under disc springs. In layman’s language, a disc spring refers to a circular element that deforms to a short height when you subject it to a load along its symmetrical axis.

Belleville washer comes in the form of a convex disc that is supported on its outer part. It uses an opposing force at the center part of the disc. This disc spring can generate high force in a short spring length without moving a lot during compression.

You can use the Belleville washer to apply pre-load to a bearing surface or bolted joints. It is possible to engineer this disc spring to deliver loading profiles that other elements such as coiled springs cannot. This disc spring can support a big load with minimum weight requirements and space.

You can use Belleville washer in bolted applications since it provides high tension. The disc spring is also suitable for dampening function due its shock absorbing capabilities. It exerts even pressure which remains constant making it suitable for situations wear tension losses due to wearing of parts or thermal contraction.

Configuring Belleville washer in stacks or single spring allows it to support a large load. Stacking Belleville washers can help you produce a linear or regressive load-vs-deflection trend. The stack options include series stacks or parallel stacks. Parallel stacks are meant to raise the maximum load allowance as you add each Belleville washer. When using Belleville washer as a stack in parallel units, you should consider the amount of friction. Stacking creates sliding friction at the moving surfaces causing deflection.

Series stacks can raise the amount of travel. You can also combine both series and parallel stacks when you need a better performance. This combination can fine tune the spring characteristics to suit your application needs.

Pros

● It works better than a coil spring due to its high load capacity

● You can adjust the load characteristics by stacking

● It absorbs shock

Cons

● They are bulky

● Not ideal for light applications

This washer supports a high load due to its conical configuration with minimal deflections. They are designed to solve problems such as vibration as well as thermal expansion or contraction.

A coil spring contains a coiled metal which is loosely attached. It is ideal for light applications. Belleville washer is strong and meant for heavy duty use due to the use of a conical spring and a raised center.

Manufacturers use stainless steel to produce this disc springs. The material is corrosion resistant, and they include a coating that also extends the lifespan of the washer.

Yes. As long as the Belleville washer is still in good condition showing no signs of being damaged, you can reuse it. Make sure that its height is within tolerance before reusing it.

Will the dimensions of this washer change once it is compressed?

Yes, but the inner and outer changes in dimension do not affect the performance of the washer.

From my Belleville washer review, I discovered that this washer is different from others such as bespoke springs and coil springs. It is a conical spring that has a raised center forming the shape of a cone. Belleville washer can easily manage a heavy load and distribute its weight uniformly to offer great stability. It can remain stable under pressure without the risk of deforming. I like the fact that they are strong and can last longer than traditional springs.